Call Us On

+91-9773159000

+91-7304985566

Leader in Air-Conditioning Systems, Parts, Services & HVAC Solutions

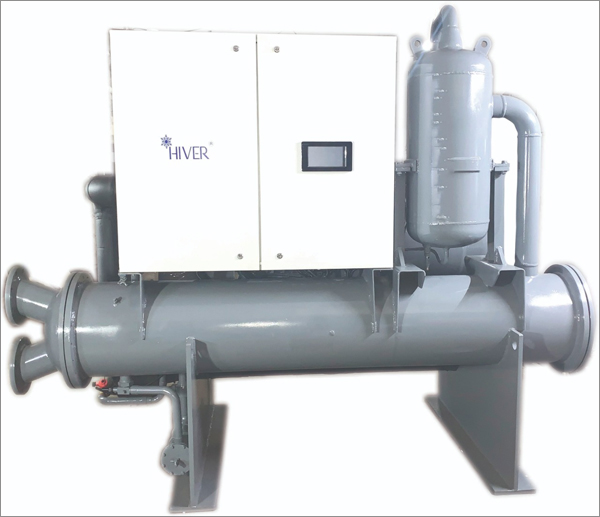

Hiver offers a variety of Scroll & Screw type Low Temperature Brine Chillers for a wide range of capacities from 01 tons to 400 tons for comfort and process cooling applications with medium GWP HFCs R134A, R404, R407C and R410A refrigerant options.

Our Scroll & Screw type Low Temperature Brine Chillers can reduce your total cost of ownership because they are engineering for lower life cycle costs and reliability through design simplicity. Our compressor technology is direct drive, low speed with only two rotating parts for high reliability and efficiency. Optimized compressor parts profiles are designed specifically for brine applications to optimize full and part-load efficiency. Our ‘’Smart H’’ Microprocessor provides greater reliability through a proactive control strategy, safety functions with simple diagnostics and easy interface with any building automation / energy management using a single twisted pair of wires.

Hiver Low Temperature Brine Chillers are the right choice for right temperature control in virtually any application.

Our compact Low Temperature Brine Chillers install easily and quickly into most building / factory layouts, making them ideal choices for retrofit or new building designs.

Hiver HBS, HBD & HBM series brine chillers are a solution when cooling medium is water with glycol and this occurs when low fluid temperature is demanded or glycol must be added to the cooling water in order to protect it from freezing.

Our systems provide constant supply of chilled propylene glycol from -250C / +250C. Ethylene glycol can be also used but not in applications where glycol circuits can be in contact with food products.

Hiver Brine Chillers can be equipped with integrated water-cooled condenser or can operate with a remote air-cooled or evaporative condenser. They can be for outdoor installation or for indoor installation in a machinery room.

Our brine chillers are equipped with a special regulating mechanism allowing unceasing smooth operation even in -200C ambient temperature.

Chilled glycol pumping system and storage tank can be contained inside the unit or can be assembled separately in a compact metal base for easy installation. Pumping system can be one circuit-loop or forming primary and secondary circuits for best adjustability to the cooling demand and significant energy saving.

In many applications a brine mixture auto-refill system is recommended. This system provides storage of already prepared mixture of glycol and water and manually or automatically refills the circuits with the lost fluid quantity. Also it detects fluid leakage by means of abnormal pressure drop and generates alarm.